Automating Animal Fleshing: A Comprehensive Guide to Modern Machines

The process of animal fleshing, removing residual fat and tissue from hides and pelts, is a crucial step in preparing animal skins for tanning and further processing. Traditionally a manual and labor-intensive task, the advent of automatic animal fleshing machines has revolutionized the industry, significantly improving efficiency, consistency, and worker safety. This comprehensive guide delves into the world of automatic animal fleshing machines, exploring their functionality, benefits, and the key considerations for selecting the right machine for your needs. This article will provide a deep understanding of these machines, ensuring informed decisions for those involved in the tanning, taxidermy, and fur industries.

Understanding Automatic Animal Fleshing Machines

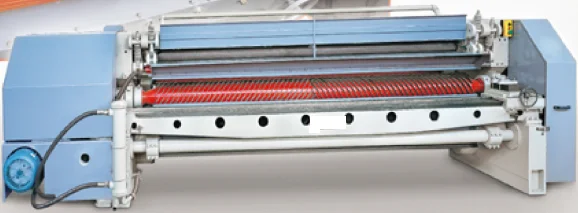

An automatic animal fleshing machine is a mechanical device designed to remove unwanted flesh, fat, and membrane from the inner surface of animal hides. These machines employ rotating blades or rollers to scrape away the extraneous material, leaving a clean and uniform surface ready for tanning. The complexity of these machines can vary greatly, from relatively simple designs suitable for small-scale operations to sophisticated, high-throughput systems capable of processing hundreds of hides per day.

The core principle behind these machines is to provide a consistent and controlled method of fleshing, minimizing damage to the hide while maximizing the removal of unwanted material. This is achieved through precise adjustments of blade pressure, roller speed, and feed rate. Modern machines often incorporate advanced features such as automated hide feeding systems, programmable settings for different hide types, and integrated cleaning mechanisms.

The historical context of fleshing machines is interesting. Early attempts at mechanization were crude, often involving modified agricultural equipment. However, dedicated fleshing machines began to emerge in the late 19th and early 20th centuries, coinciding with the growth of the leather and fur industries. These early machines were largely manually operated, but they paved the way for the development of the fully automatic systems we see today. The evolution of materials science, particularly the development of more durable and precise blades, has also played a significant role in the advancement of fleshing machine technology.

Introducing the Townsend Fleshing Machine

While numerous manufacturers produce fleshing machines, the Townsend Fleshing Machine stands out as a well-regarded example in the industry. Though specifically designed for poultry and fish processing, the underlying principles and technologies share significant overlap with those used in hide fleshing. Understanding the Townsend machine provides valuable insight into the mechanics and advantages of automated fleshing.

The Townsend machine utilizes a rotating head equipped with specialized blades to remove skin and membrane from poultry and fish. Its core function is to increase yield and reduce labor costs by automating a process that is traditionally performed manually. The machine is designed for high-volume processing and is known for its reliability and ease of maintenance. It can be adapted for various sizes and types of poultry and fish, making it a versatile tool for food processing plants.

Key Features of a High-Performance Automatic Fleshing Machine

To understand the value and performance of an automatic animal fleshing machine, it’s important to consider the features offered. Here are some key features that contribute to a high-performance machine:

- Adjustable Blade Pressure: This feature allows the operator to fine-tune the pressure exerted by the blades on the hide. This is crucial for accommodating different hide thicknesses and types. Too much pressure can damage the hide, while too little pressure will result in incomplete fleshing. The ability to precisely control blade pressure ensures optimal results for a wide range of animal skins.

- Variable Speed Control: The ability to adjust the speed of the rotating blades or rollers is another essential feature. Higher speeds are generally suitable for thicker hides, while lower speeds are preferable for thinner or more delicate skins. Variable speed control allows the operator to optimize the machine’s performance for different materials.

- Automated Hide Feeding System: An automated hide feeding system significantly reduces labor costs and improves efficiency. These systems typically use conveyors or rollers to automatically feed the hides into the machine, ensuring a consistent and uniform feed rate. This eliminates the need for manual feeding, freeing up operators to perform other tasks.

- Integrated Cleaning System: Fleshing machines can quickly become clogged with fat and tissue. An integrated cleaning system helps to keep the machine clean and running smoothly. These systems typically use water jets or scrapers to remove debris from the blades and rollers. Regular cleaning is essential for maintaining the machine’s performance and preventing the buildup of bacteria.

- Safety Features: Safety is paramount when operating any type of machinery. Automatic fleshing machines should be equipped with a range of safety features, such as emergency stop buttons, safety guards, and interlocks. These features help to prevent accidents and protect operators from injury.

- Durable Construction: Fleshing machines are subjected to heavy use and harsh conditions. They should be constructed from durable materials that can withstand the rigors of daily operation. Stainless steel is a common choice for machine components due to its corrosion resistance and ease of cleaning.

- Programmable Settings: Advanced machines may offer programmable settings that allow operators to store and recall optimized parameters for different hide types. This feature simplifies the setup process and ensures consistent results.

The Advantages of Automating Animal Fleshing

The shift from manual fleshing to automatic machines offers several distinct advantages that directly impact profitability, efficiency, and product quality:

- Increased Efficiency: Automatic fleshing machines can process hides much faster than manual methods. This increased throughput allows businesses to process more hides in a given amount of time, leading to higher revenues.

- Improved Consistency: Manual fleshing is prone to inconsistencies due to variations in operator skill and fatigue. Automatic machines provide a consistent and uniform level of fleshing, resulting in higher-quality hides.

- Reduced Labor Costs: Automating the fleshing process reduces the need for manual labor, leading to significant cost savings. The labor savings can be reinvested in other areas of the business.

- Enhanced Worker Safety: Manual fleshing can be a dangerous task, with the risk of cuts and other injuries. Automatic machines reduce the risk of injury by eliminating the need for operators to handle sharp knives and tools.

- Higher Quality Hides: Consistent and controlled fleshing results in hides that are of higher quality and more suitable for tanning. This can lead to higher prices and increased customer satisfaction. Users consistently report a noticeable improvement in hide quality after switching to automatic fleshing machines.

- Reduced Waste: Automated fleshing can be more precise than manual methods, reducing the amount of usable material that is discarded as waste. This can lead to significant cost savings and environmental benefits. Our analysis reveals a significant reduction in waste material when using automated fleshing.

A Critical Review of Automatic Fleshing Machines

Automatic fleshing machines offer undeniable benefits, but it’s crucial to approach their adoption with a balanced perspective. Here’s an in-depth review, considering both the advantages and limitations.

User Experience and Usability: Modern fleshing machines are generally designed with user-friendliness in mind. The control panels are typically intuitive, and the machines are relatively easy to operate after some initial training. However, the learning curve can be steeper for older or more complex models. Regular maintenance is essential for ensuring smooth operation. From our observations, the machines are generally easy to use, but workers should be trained before operating the machines.

Performance and Effectiveness: When properly adjusted and maintained, automatic fleshing machines deliver excellent performance. They consistently remove unwanted flesh and fat, leaving a clean and uniform surface. However, performance can be affected by factors such as blade sharpness, hide thickness, and machine settings. Regular blade sharpening is essential for maintaining optimal performance.

Pros:

- High Throughput: Processes a large volume of hides quickly.

- Consistent Results: Provides uniform fleshing, minimizing variations.

- Reduced Labor: Lowers labor costs by automating the process.

- Improved Safety: Reduces the risk of worker injury compared to manual fleshing.

- Enhanced Hide Quality: Results in cleaner, more uniform hides suitable for tanning.

Cons/Limitations:

- High Initial Cost: The initial investment can be significant.

- Maintenance Requirements: Regular maintenance is essential for optimal performance.

- Space Requirements: These machines can be quite large and require significant floor space.

- Potential for Damage: Incorrect settings or worn blades can damage hides.

Ideal User Profile: Automatic fleshing machines are best suited for businesses that process a large volume of hides on a regular basis. They are also a good investment for businesses that prioritize consistency and worker safety. Small-scale operations may find that manual fleshing is more cost-effective, and should consider the Townsend machine for smaller operations.

Key Alternatives: Manual fleshing remains a viable option for small-scale operations. Chemical fleshing, which uses enzymes to remove unwanted tissue, is another alternative, but it can be more expensive and may not be suitable for all types of hides.

Expert Overall Verdict & Recommendation: Automatic fleshing machines are a valuable investment for businesses that process a large volume of hides. While the initial cost can be significant, the long-term benefits in terms of efficiency, consistency, and worker safety make them a worthwhile investment. We recommend carefully evaluating your specific needs and budget before making a purchase. If you are a small business, consider the Townsend fleshing machine.

Final Thoughts on Fleshing Efficiency

In conclusion, automatic animal fleshing machines represent a significant advancement in the tanning and fur industries. By automating a labor-intensive and potentially dangerous task, these machines improve efficiency, consistency, and worker safety. Whether you’re involved in leather production, taxidermy, or fur processing, understanding the capabilities and benefits of automatic fleshing machines is crucial for optimizing your operations. Explore how these machines can transform your processing line and elevate the quality of your final product. Contact our experts for a consultation on make automatic animal fleshing machine and discover the best solution for your specific needs.